Custom Computer Heat Sink Manufacturing Excellence

Precision-engineered thermal management solutions delivering superior cooling performance for high-performance electronics, automotive, and renewable energy applications.

25

5-Axis CNC Centers

±0.01mm

Tolerance Precision

2-4

Weeks Lead Time

15+

Years Manufacturing

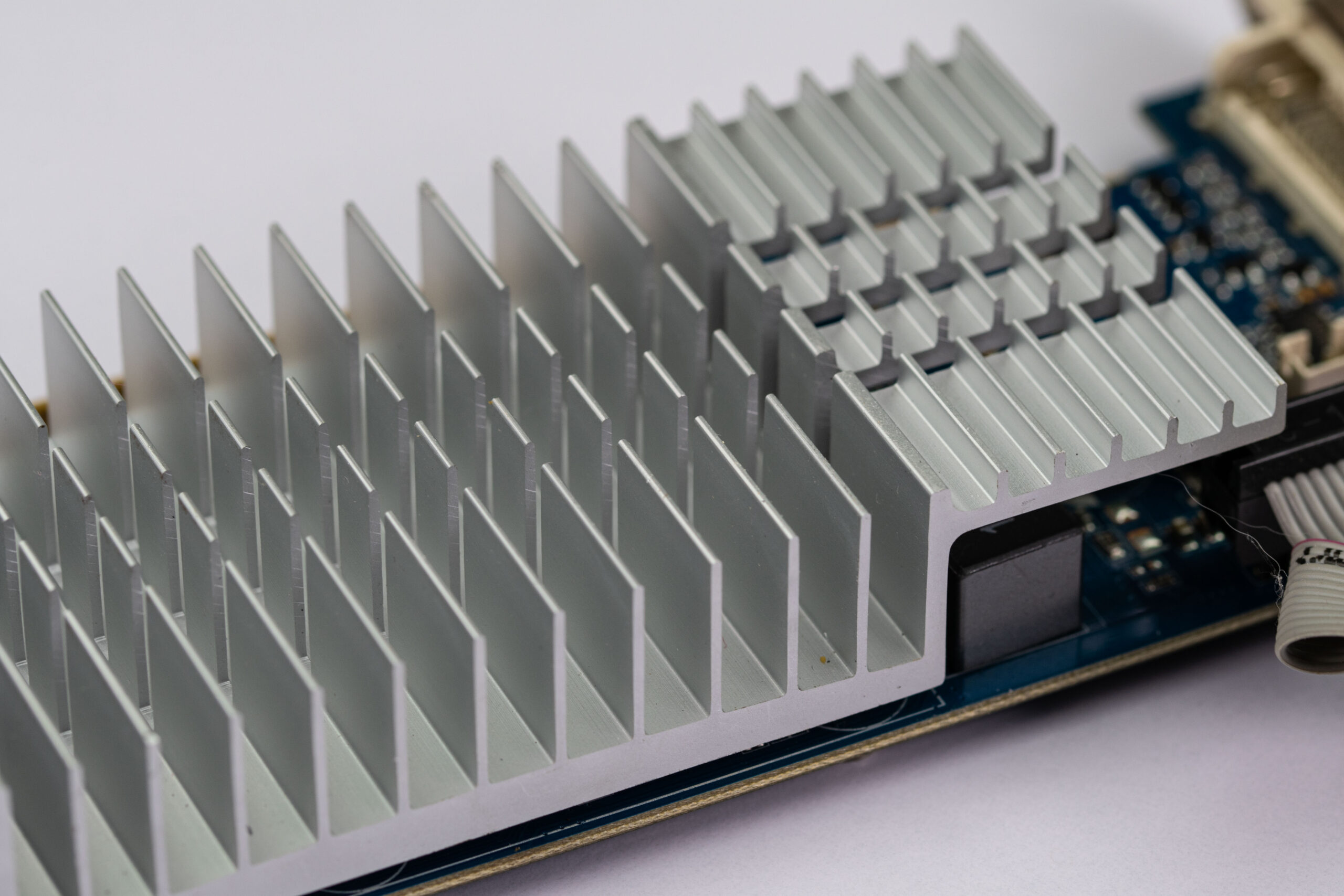

Why Choose Our Heat Sink Solutions

Advanced engineering and precision manufacturing deliver unmatched thermal performance for your most demanding applications.

Superior Heat Dissipation

Engineered fin geometries and optimized surface area deliver exceptional thermal conductivity and maximum heat transfer efficiency for critical cooling applications.

Lightweight Design

High-grade aluminum construction provides outstanding strength-to-weight ratio, reducing overall system weight while maintaining structural integrity.

Precision Manufacturing

State-of-the-art CNC machining achieves tolerances up to ±0.01mm, ensuring perfect fit, optimal thermal contact, and consistent performance.

High Thermal Conductivity

Premium aluminum alloys with thermal conductivity up to 229 W/m·K ensure rapid heat transfer and optimal cooling performance.

Corrosion Resistance

Advanced surface treatments including anodizing and protective coatings provide long-lasting protection against harsh environmental conditions.

Sustainable Materials

100% recyclable aluminum materials support environmentally responsible manufacturing while delivering exceptional performance and durability.

Comprehensive Cooling Solutions

Tailored thermal management solutions engineered to meet diverse cooling requirements across industries and applications.

Air Cooling Systems

- Natural convection designs for passive cooling

- Forced air cooling with optimized airflow

- Advanced fin geometry for maximum surface area

- Cost-effective thermal management solution

Liquid Cooling Systems

- Cold plate technology for direct contact cooling

- Embedded cooling channels for efficient heat transfer

- High-performance cooling for demanding applications

- Ideal for server and data center environments

Passive Cooling Systems

- Silent operation with zero moving parts

- Maximum reliability and longevity

- Maintenance-free operation

- Perfect for noise-sensitive environments

Industries We Serve

Delivering specialized thermal management solutions across diverse industries with mission-critical cooling requirements.

Personal Computing

High-performance CPU and GPU cooling solutions for gaming rigs, workstations, and enthusiast builds.

Data Centers & Servers

Enterprise-grade cooling solutions for high-density server environments and critical infrastructure applications.

Mobile Devices

Ultra-thin cooling solutions for laptops, tablets, and portable devices requiring compact thermal management.

Specialized Applications

Custom solutions for gaming consoles, industrial computers, embedded systems, and IoT devices.

Frequently Asked Questions

Get answers to common questions about our heat sink manufacturing services and technical capabilities.

What are your typical lead times?

Standard custom heat sinks: 2-4 weeks depending on complexity and quantity. Rapid prototyping available in 5-7 business days. Rush orders can be accommodated with expedited processing for urgent requirements.

What materials do you work with?

We specialize in high-grade aluminum alloys (6061-T6, 6063-T5, 7075-T6, 1050-H14) and copper (C101, C110) selected for optimal thermal conductivity, durability, and manufacturability.

What manufacturing tolerances can you achieve?

We maintain dimensional tolerances as tight as ±0.01mm with surface roughness from Ra 0.8 to 3.2μm. Our advanced CNC equipment ensures consistent precision across all production runs.

Do you provide prototyping services?

Yes, we offer rapid prototyping with typical delivery in 5-7 business days. This allows for design validation, thermal testing, and fit verification before committing to full production.

What surface treatments are available?

We offer comprehensive surface treatments including anodizing (Type II & III), powder coating, sandblasting, electroplating, nickel plating, chromate conversion, and passivation treatments.

What quality certifications do you maintain?

We maintain ISO 9001:2015 certification and follow AS9100 aerospace standards. All products undergo comprehensive quality inspection using calibrated CMM equipment and certified measurement systems.

Ready to Optimize Your Thermal Management Manufacturing?

Contact our engineering team for custom aluminum extrusion heat sink manufacturing services tailored to your specific requirements.