What Is 8620 Steel?

8620 steel is a low-alloy steel known for its versatility and excellent mechanical properties. It belongs to the family of nickel-chromium-molybdenum steels, which are prized for their strength, toughness, and ability to be case-hardened. The designation “8620” comes from the SAE-AISI numbering system, where the numbers indicate the alloy’s composition and characteristics. Specifically, 8620 steel contains small amounts of nickel, chromium, and molybdenum, which contribute to its durability and performance under stress.

This alloy is particularly valued in the machining industry because it can be easily worked while maintaining structural integrity. Its ability to undergo heat treatment, such as carburizing, makes it ideal for components that require a hard surface and a tough core.

Composition of 8620 Steel

- Carbon (C): 0.18–0.23% – Provides hardness and strength, particularly after heat treatment.

- Nickel (Ni): 0.40–0.70% – Enhances toughness and resistance to impact.

- Chromium (Cr): 0.40–0.60% – Improves corrosion resistance and hardenability.

- Molybdenum (Mo): 0.15–0.25% – Increases strength and resistance to wear and fatigue.

- Manganese (Mn): 0.70–0.90% – Contributes to strength and workability.

- Silicon (Si): 0.15–0.35% – Improves elasticity and strength.

- Iron (Fe): Balance – The primary base metal, providing the structural foundation.

This precise mix of elements allows 8620 steel to achieve a balance of hardness, ductility, and toughness, making it suitable for a variety of machining processes. The alloy’s composition also enables it to respond well to heat treatments, which further enhance its performance in specific applications.

Properties of 8620 Steel

The properties of 8620 steel make it a standout choice for manufacturers. Its ability to combine strength, toughness, and machinability sets it apart from other alloys. Below, we explore the mechanical and physical properties that define this material.

Mechanical Properties

- Tensile Strength: In its annealed state, this alloy typically has a tensile strength of around 530–630 MPa. After carburizing and hardening, this can increase significantly, making it suitable for heavy-duty components.

- Yield Strength: The yield strength ranges from 385–460 MPa in the annealed condition, providing a good balance of flexibility and strength.

- Hardness: In its annealed state, I has a hardness of approximately 149–197 HB (Brinell Hardness). After case hardening, the surface hardness can reach 55–60 HRC (Rockwell C), while the core remains tough.

- Elongation: The alloy exhibits good ductility, with elongation typically around 20–25% in its annealed state, allowing it to absorb impacts without fracturing.

- Fatigue Resistance: Thanks to the presence of molybdenum and nickel, the steel offers excellent fatigue resistance, making it ideal for components subjected to cyclic loading.

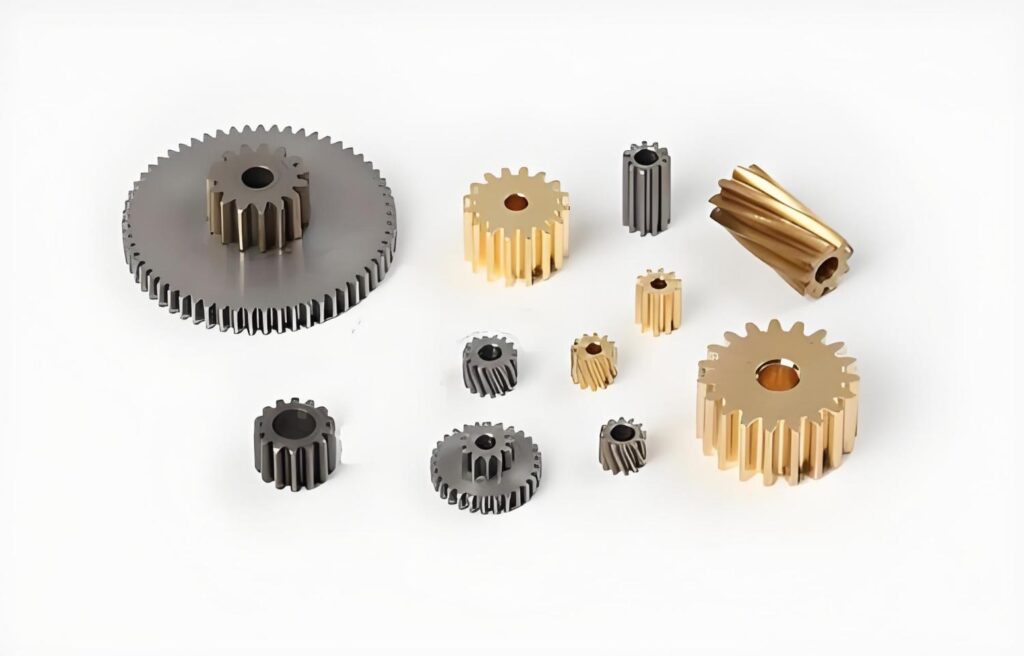

These mechanical properties make 8620 steel a preferred material for parts that require both strength and durability, such as gears, pinions, and camshafts.

Physical Properties

- Density: Approximately 7.85 g/cm³, typical for low-alloy steels.

- Thermal Conductivity: Around 46.6 W/m·K, allowing efficient heat dissipation in high-temperature applications.

- Melting Point: Roughly 1,427–1,538°C, ensuring stability under high-temperature machining processes.

- Magnetic Properties: Itl is ferromagnetic, which can be advantageous in certain applications, such as electromagnetic components.

These physical properties, combined with its mechanical strengths, make 8620 steel a reliable choice for precision machining projects that demand consistency and performance.

Applications of 8620 alloy steel

8620 steel’s versatility makes it a popular choice across a wide range of industries. Its ability to be machined, heat-treated, and case-hardened allows it to meet the demands of various applications. Some common uses include:

- Automotive Industry: It is widely used in the production of gears, pinions, and crankshafts due to its strength and wear resistance. It’s a go-to material for transmission components that require a hard surface and a tough core.

- Aerospace: The alloy’s fatigue resistance and toughness make it suitable for aircraft components such as landing gear parts and fasteners.

- Heavy Machinery: It is used in the manufacturing of heavy-duty equipment, including shafts, axles, and hydraulic components, where durability is essential.

- Oil and Gas: The alloy’s ability to withstand high stress and resist wear makes it ideal for drilling equipment and other components exposed to harsh environments.

- Tooling and Dies: In tool-making, this steel is used for dies and molds that require a balance of hardness and machinability.

These applications highlight the alloy’s ability to perform in demanding conditions, making it a staple in industries that prioritize reliability and precision.

Advantages and Disadvantages of 8620 Steel

Like any material, 8620 steel has its strengths and limitations. Understanding these can help manufacturers make informed decisions about when to use this alloy.

Advantages

- Excellent Machinability: In its annealed state, the steel is easy to machine, allowing for precise shaping and finishing.

- Case-Hardening Capability: The alloy responds well to carburizing, resulting in a hard surface and a tough core, ideal for wear-resistant components.

- Balanced Properties: The combination of strength, toughness, and ductility makes 8620 steel versatile for a wide range of applications.

- Cost-Effective: Compared to high-alloy steels, 8620 steel is relatively affordable, offering high performance at a lower cost.

- Fatigue Resistance: The presence of nickel and molybdenum enhances its ability to withstand cyclic loading, reducing the risk of failure in dynamic applications.

Disadvantages

- Limited Corrosion Resistance: While 8620 steel offers some corrosion resistance due to its chromium content, it is not as resistant as stainless steel and may require coatings in corrosive environments.

- Heat Treatment Complexity: Achieving the desired hardness and toughness requires precise heat treatment processes, which can add to production costs.

- Not Suitable for Extreme Temperatures: While 8620 steel performs well in many conditions, it may not be ideal for applications involving extreme heat or cold.

By weighing these pros and cons, manufacturers can determine whether 8620 steel is the right choice for their specific needs.

Does 8620 Steel Rust?

One common question about 8620 steel is whether it is prone to rust. Like most low-alloy steels, 8620 steel is not inherently corrosion-resistant. Its chromium content provides some protection against rust, but it is not comparable to stainless steel, which contains higher levels of chromium and nickel. In environments exposed to moisture, salt, or chemicals, it may rust if not properly protected.

To prevent rust, manufacturers often apply protective coatings, such as oil, paint, or plating, to components made from 8620 steel. Additionally, proper storage and maintenance can extend the lifespan of parts made from this alloy. For applications in highly corrosive environments, alternative materials like stainless steel or corrosion-resistant coatings may be considered.

Why Choose 8620 carbon steel for Your Machining Needs?

8620 steel’s combination of machinability, strength, and toughness makes it a top choice for manufacturers looking to produce high-quality components. Its ability to be case-hardened ensures that parts can withstand wear and stress, while its cost-effectiveness makes it an attractive option for large-scale production. Whether you’re crafting gears for an automotive transmission or shafts for heavy machinery, 8620 steel delivers reliable performance.

Precionn: Your Partner in Precision Machining

When it comes to leveraging the benefits of 8620 steel, Precionn is your trusted partner in the machining industry. With years of expertise in working with high-performance alloys, Precionn specializes in delivering precision-machined components that meet the highest standards of quality and durability. Our state-of-the-art facilities and skilled team ensure that every part, whether made from 8620 steel or other materials, is crafted with precision and care.

At Precionn, we understand the importance of selecting the right material for your project. That’s why we offer comprehensive solutions, from material selection to final production, to help you achieve your goals. Visit our website to learn more about how we can support your machining needs with 8620 steel and other advanced materials.