Inconel 718 is a name that resonates across industries like aerospace, energy, and manufacturing, where strength, durability, and resistance to extreme conditions are non-negotiable. This nickel-based superalloy has earned its reputation as a go-to material for components that must withstand intense heat, corrosion, and mechanical stress. This blog dives into the world of Inconel 718, exploring its composition, properties, applications, and processing techniques, while shedding light on why it remains a top choice for engineers and manufacturers worldwide.

What is Inconel 718?

Inconel 718, is a nickel-chromium-based superalloy designed for high-strength and high-temperature applications. Developed in the mid-20th century, it belongs to the Inconel family of alloys, known for their exceptional performance in harsh environments. What sets its ability to maintain structural integrity under extreme conditions, making it a favorite in industries requiring reliability and precision.

This superalloy is particularly valued for its resistance to oxidation, corrosion, and creep at elevated temperatures. Its unique combination of strength and workability allows it to be fabricated into complex components. Whether in aerospace or oil and gas, Inconel 718 delivers performance where other materials falter.

Composition of Inconel 718

The chemical composition of it is carefully balanced to achieve high performance. Here is a breakdown of its primary elements:

- Nickel (Ni): 50-55%

- Chromium (Cr): 17-21%

- Iron (Fe): Balance

- Niobium (Nb) + Tantalum (Ta): 4.75-5.5%

- Molybdenum (Mo): 2.8-3.3%

- Titanium (Ti): 0.65-1.15%

- Aluminum (Al): 0.2-0.8%

- Cobalt (Co): Up to 1.0%

- Carbon (C): Max 0.08%

- Manganese (Mn), Silicon (Si), Sulfur (S), Phosphorus (P): Trace amounts

Properties of Inconel 718

Mechanical Properties

It is celebrated for its high tensile, yield, and creep-rupture strength. Its age-hardenable structure allows it to retain its mechanical integrity even under high thermal stress and fatigue conditions.

- Yield strength: Approximately 1030 MPa (150,000 psi) at room temperature

- Tensile strength: Around 1240 MPa (180,000 psi)

- Elongation: Up to 30% depending on heat treatment

- Hardness: Typically around 331 BHN (Brinell Hardness Number)

These characteristics make it suitable for structural components in aerospace and power generation turbines, where reliability is critical.

Physical Properties

It also exhibits impressive physical characteristics:

- Density: ~8.19 g/cm^3

- Thermal conductivity: Around 11.4 W/m·K at 100°C

- Melting point: Approximately 1,350–1,390°C

- Melting temperature: Falls within the same range, highlighting its suitability for high-heat environments

Its low thermal conductivity and high resistance to oxidation make it ideal for situations where temperature regulation and durability are essential.

Applications of Inconel 718

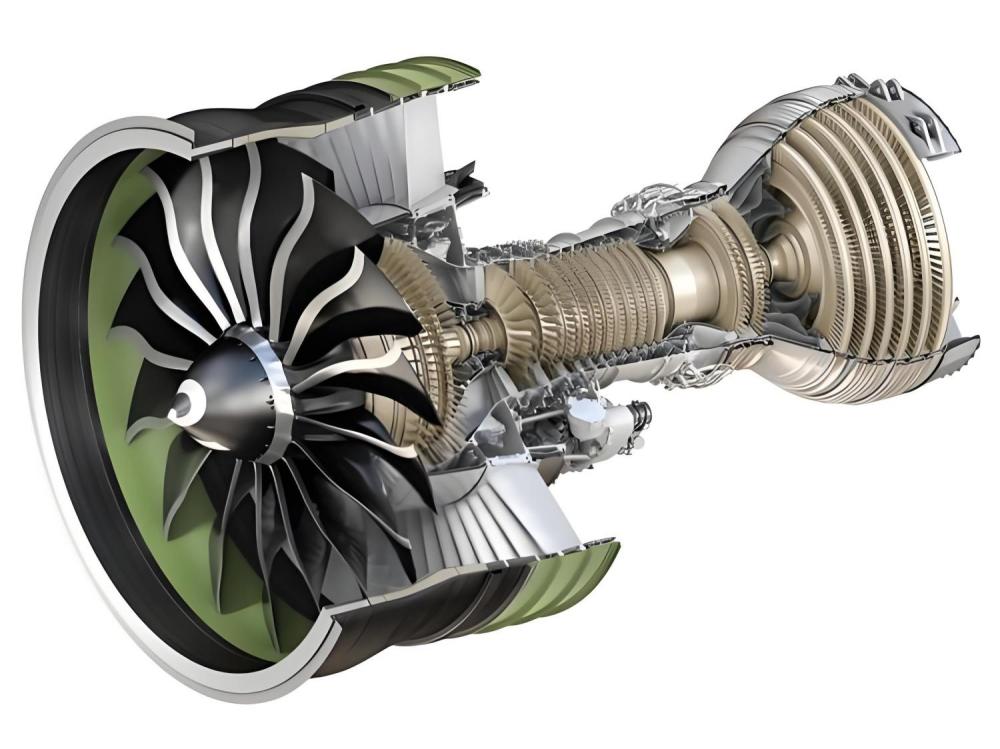

Aerospace

The aerospace industry is one of the largest consumers of Inconel 718. Jet engines, turbine blades, and exhaust systems rely on the alloy’s ability to withstand temperatures exceeding 1,000°C. Its high strength-to-weight ratio, derived from it density, makes it ideal for aircraft components where weight reduction is critical.

Energy Sector

In the oil and gas industry, It is used in downhole tools, valves, and fittings exposed to corrosive environments. Its resistance to pitting and crevice corrosion ensures reliability in offshore drilling and gas extraction. The alloy is also used in nuclear reactors, where its ability to resist radiation-induced stress corrosion cracking is invaluable.

Additive Manufacturing

The rise of 3D printing Inconel 718 has opened new possibilities for creating complex geometries with precision. It is used in additive manufacturing to produce lightweight, high-strength components for aerospace and medical applications. This technology allows for rapid prototyping and customization, reducing waste and production time.

Automotive and Industrial

Inconel 718 bolts and fasteners are common in high-performance automotive applications, such as racing engines, where durability under extreme conditions is essential. The alloy is also used in industrial gas turbines and chemical processing equipment, where its corrosion resistance and strength are critical.

Inconel 718 Common Processing

Processing this alloy requires specialized techniques due to its high strength and workability. Manufacturers like Precionn employ advanced machining and fabrication methods to shape this superalloy into precise components.

Machining

Machining this alloy is complex, often resulting in Inconel 718 turnings, a valuable byproduct for recycling. Due to its strength and work hardening properties, slower cutting speeds and rigid setups are essential to achieve precision.

Heat Treatment

Heat treatment is critical for optimizing Inconel 718’s properties. The alloy is typically solution-treated at 980-1,060°C, followed by aging to enhance its strength and hardness. This process ensures that components meet the stringent requirements of industries like aerospace.

Additive Manufacturing

As mentioned earlier, 3D printing Inconel 718 using Inconel 718 powder has revolutionized manufacturing. This process allows for the creation of complex parts with minimal material waste, making it cost-effective for high-value applications.

Stamping and Forming

Custom Inconel 718 stamped parts are produced using advanced stamping techniques. These parts are used in applications requiring intricate shapes and high strength, such as aerospace brackets and fittings. Precision stamping ensures consistency and quality in every component.

Powder Metallurgy

Inconel 718 powder is used in additive manufacturing and powder metallurgy processes. It allows for the creation of complex geometries with high performance and minimal waste.

Haynes 282 vs Inconel 718

When comparing superalloys, Haynes 282 often comes up as an alternative to Inconel 718. Both alloys are nickel-based and designed for high-temperature applications, but they have distinct differences.

- Composition: Haynes 282 contains higher levels of cobalt and lower niobium compared to Inconel 718, affecting their strengthening mechanisms.

- Temperature Resistance: Haynes 282 offers superior creep resistance at temperatures above 900°C, while Inconel 718 excels up to 700°C.

- Weldability: Inconel 718 is easier to weld, making it more versatile for certain manufacturing processes.

- Cost: The Inconel 718 price is generally lower than Haynes 282, making it a more cost-effective choice for many applications.

While Haynes 282 is preferred for ultra-high-temperature applications, Inconel 718’s balance of cost, workability, and performance makes it a go-to choice for a broader range of uses.

Advantages and Disadvantages of Inconel 718

Like any material, the alloy has its pros and cons. Understanding these can help manufacturers make informed decisions about its use.

Advantages

- High Strength: The alloy’s yield strength makes it ideal for load-bearing components in extreme environments.

- Corrosion Resistance: Its resistance to oxidation and chemical corrosion ensures longevity in harsh conditions.

- Temperature Stability: The alloy melting temperature allows it to perform in high-heat applications without losing integrity.

- Versatility: From Inconel 718 bolts to 3D-printed components, the alloy can be used in a wide range of applications.

Disadvantages

- Machining Challenges: The alloy’s hardness and strength make it difficult to machine, requiring specialized tools and expertise.

- Cost: The Inconel 718 price is higher than many other materials, which can be a factor for budget-conscious projects.

- Recycling Considerations: While Inconel 718 scrap price can offset costs, recycling requires specialized processes due to the alloy’s composition.

Despite these challenges, the benefits of Inconel 718 often outweigh the drawbacks, especially for applications where performance is non-negotiable.

The Market and Pricing

Understanding the economic aspect of this alloy is essential for industrial buyers and engineers.

- Inconel 718 price: It varies based on form, market conditions, and alloy availability. Typically, it ranges between $25 to $40 per pound.

- Inconel 718 scrap price: Due to its nickel content, scrap prices often hover between $5 to $15 per pound, subject to market fluctuations.

These figures can vary based on the source and demand in the metal recycling industry.

Precionn’s Expertise in Inconel 718

At Precionn, we understand the unique challenges and opportunities of working with Inconel 718. As a leader in the machining industry, Precionn specializes in crafting precision components from this superalloy. Our state-of-the-art facilities and skilled team ensure that every component meets the highest standards of quality and performance. Whether you’re in aerospace, energy, or automotive, Precionn is your trusted partner for Inconel 718 solutions. Visit our website to learn more about how we can bring your projects to life with precision and expertise.