Inconel 625 is a remarkable material that has captured the attention of industries ranging from aerospace to marine engineering. Known for its exceptional strength, corrosion resistance, and versatility, this nickel-based superalloy plays a critical role in applications where durability and performance are paramount. This blog post delves into the world of Inconel 625, exploring its composition, properties, uses, advantages, and more, while addressing common questions about this fascinating material. Whether you’re an engineer, or machinist about advanced materials, this guide offers valuable insights into why this alloy stands out in the world of high-performance alloys.

What is Inconel 625?

The superalloy is a nickel-chromium-molybdenum alloy renowned for its ability to withstand extreme environments. Developed to provide exceptional resistance to corrosion and high temperatures, it belongs to the family of superalloys—materials engineered to perform under intense conditions where standard metals would fail. The alloy’s unique combination of strength, toughness, and resistance to oxidation makes it a go-to choice for industries that demand reliability in harsh settings.

This superalloy was first introduced in the 1960s and has since become a staple in applications requiring resilience against heat, pressure, and corrosive substances. From jet engines to chemical processing equipment, Inconel 625’s versatility has cemented its place as a critical material in modern engineering.

Inconel 625 Chemical Composition

The performance of Inconel 625 stems from its carefully balanced composition. The alloy is primarily composed of nickel, which forms the base for its corrosion resistance and strength. Other elements are strategically added to enhance specific properties, creating a material that excels in demanding environments.

- Nickel (Ni): 58% minimum – Provides the foundation for corrosion resistance and high-temperature stability.

- Chromium (Cr): 20-23% – Enhances oxidation resistance and strength.

- Molybdenum (Mo): 8-10% – Improves resistance to pitting and crevice corrosion.

- Niobium (Nb) + Tantalum (Ta): 3.15-4.15% – Contributes to high-temperature strength and creep resistance.

- Iron (Fe): 5% maximum – Adds to the alloy’s overall strength.

- Trace Elements: Small amounts of carbon, manganese, silicon, sulfur, aluminum, titanium, cobalt, and phosphorus are included to fine-tune the alloy’s properties.

Properties of Inconel 625

Mechanical Properties

- Tensile Strength: The superalloy tensile strength of approximately 120-160 ksi (827-1103 MPa) at room temperature, allowing it to withstand significant loads.

- Yield Strength: With a yield strength of around 60-110 ksi (414-758 MPa), it resists deformation under stress.

- Elongation: The alloy exhibits good ductility, with an elongation of about 30-60%, enabling it to absorb energy without fracturing.

- Fatigue Resistance: This alloy performs well under cyclic loading, making it suitable for applications involving repeated stress.

- Creep Resistance: It maintains strength and resists deformation at high temperatures, crucial for components exposed to prolonged heat.

These mechanical properties make Inconel 625 ideal for structural components in high-stress environments, such as turbine blades and pressure vessels.

Physical Properties

- Density: Approximately 8.44 g/cm³, providing a balance of strength and weight.

- Melting Point: Ranges from 2,350-2,460°F (1,290-1,350°C), allowing it to function in high-temperature environments.

- Thermal Conductivity: About 9.8 W/m·K at room temperature, enabling efficient heat dissipation.

- Specific Heat Capacity: Around 410 J/kg·K, which supports its stability across a wide temperature range.

- Corrosion Resistance: Exceptional resistance to a variety of corrosive environments, including seawater, acids, and alkalis.

These physical properties ensure that Inconel 625 can perform reliably in diverse conditions, from cryogenic temperatures to extreme heat.

Uses of Nickel Inconel Alloy 625

Inconel 625’s unique combination of properties makes it a preferred material in a wide range of industries. Its ability to withstand harsh environments and maintain performance under stress has led to its adoption in critical applications.

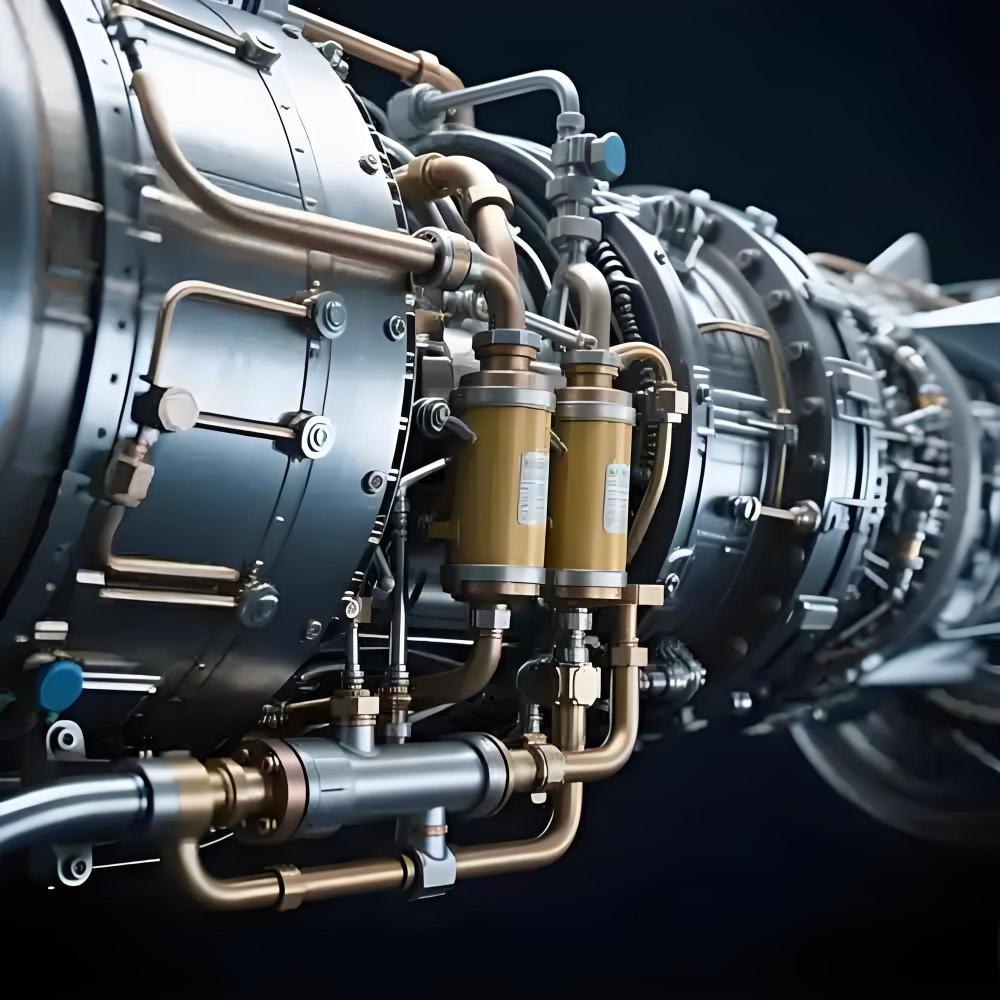

Aerospace Applications

In the aerospace industry, Inconel 625 is used in components such as turbine blades, exhaust systems, and engine ducting. Its high strength and resistance to thermal fatigue make it ideal for jet engines, where temperatures can exceed 1,800°F (982°C). The alloy’s corrosion resistance also ensures longevity in environments exposed to moisture and chemicals.

Marine Engineering

The marine industry relies on Inconel 625 for components like propeller shafts, underwater sensors, and offshore platform equipment. Its resistance to seawater corrosion and biofouling makes it a top choice for marine applications, where materials must endure constant exposure to saltwater and harsh weather conditions.

Chemical Processing

In chemical processing plants, Inconel 625 is used in reactors, heat exchangers, and piping systems. Its ability to resist acidic and alkaline environments ensures reliable performance in facilities handling corrosive substances like sulfuric acid, hydrochloric acid, and caustic soda.

Nuclear and Energy Sectors

Inconel 625 is widely used in nuclear reactors and power generation systems due to its ability to withstand high temperatures and radiation. Components such as reactor core supports and steam generator tubing benefit from the alloy’s durability and corrosion resistance.

Oil and Gas Industry

The oil and gas sector employs Inconel 625 in downhole equipment, wellhead components, and pipelines. Its resistance to sour gas environments (containing hydrogen sulfide) and high-pressure conditions makes it a reliable choice for extracting and transporting hydrocarbons.

Advantages and Disadvantages of Inconel 625

Like any material, Inconel 625 has its strengths and limitations. Understanding these can help industries make informed decisions about its use.

Advantages

- Exceptional Corrosion Resistance: This superalloy excels in resisting corrosion in harsh environments, including seawater, acids, and high-temperature oxidation.

- High Strength and Durability: Its mechanical properties ensure it can withstand extreme stress and temperatures without deforming or failing.

- Versatility: The alloy performs well across a wide temperature range, from cryogenic to over 1,800°F (982°C).

- Weldability: It can be welded without significant loss of properties, making it suitable for complex fabrications.

- Fatigue and Creep Resistance: It maintains performance under cyclic loading and prolonged high-temperature exposure.

Disadvantages

- High Cost: It is more expensive than many other alloys, such as stainless steel, due to its complex composition and manufacturing process.

- Machining Challenges: Its high strength and hardness make it difficult to machine, requiring specialized tools and expertise.

- Limited Availability: Compared to more common materials like steel or aluminum, It may have longer lead times for procurement.

- Weight Considerations: While not excessively heavy, its density is higher than some lighter alternatives like titanium, which may be a factor in weight-sensitive applications.

Despite these challenges, the benefits of Inconel 625 often outweigh its drawbacks in applications where performance and reliability are critical.

Inconel 625 vs Inconel 718

Inconel 625 and Inconel 718 are two of the most popular superalloys, but they serve slightly different purposes due to differences in their composition and properties. Comparing these alloys can help engineers choose the right material for specific applications.

Composition Comparison

Inconel 625 contains higher levels of nickel (58% minimum) and molybdenum (8-10%), which enhance its corrosion resistance. Inconel 718, on the other hand, has a slightly lower nickel content (50-55%) and includes more iron and titanium, which contribute to its high strength and precipitation-hardening capabilities.

Property Differences

- Corrosion Resistance: Inconel 625 offers superior resistance to pitting and crevice corrosion, particularly in marine and chemical environments. Inconel 718, while corrosion-resistant, is less effective in highly corrosive settings.

- Strength: Inconel 718 is designed for higher tensile and yield strength, especially after heat treatment, making it ideal for high-stress applications like turbine disks.

- Temperature Range: Inconel 625 performs better at extreme temperatures (up to 1,800°F), while Inconel 718 is optimized for slightly lower temperature ranges but excels in creep resistance.

- Weldability: 625 is easier to weld without cracking, whereas Inconel 718 requires careful welding techniques to avoid issues.

Application Differences

It is preferred in marine, chemical processing, and nuclear applications due to its corrosion resistance. Inconel 718 is more commonly used in aerospace components like turbine blades and structural parts, where high strength and fatigue resistance are critical.

The Impact of Inconel 625 on the Environment

As industries increasingly prioritize sustainability, the environmental impact of materials like Inconel 625 is an important consideration. While the alloy offers exceptional performance, its production and use have both positive and negative environmental implications.

Production and Resource Use

The production of Inconel 625 involves mining and processing nickel, chromium, and other metals, which can be energy-intensive and generate emissions. The extraction of these raw materials may also impact ecosystems if not managed responsibly. However, many manufacturers are adopting sustainable practices, such as using recycled materials and improving energy efficiency, to mitigate these effects.

Durability and Longevity

One of Inconel 625’s environmental advantages is its durability. Components made from this alloy have long service lives, reducing the need for frequent replacements and minimizing waste. Its corrosion resistance also means less maintenance and fewer chemical treatments, which can benefit the environment.

Recycling Potential

Inconel 625 is recyclable, and scrap from machining or end-of-life components can be melted down and reused. Recycling reduces the demand for virgin materials and lowers the environmental footprint of production. Industries are encouraged to implement recycling programs to maximize the sustainability of Inconel 625.

Environmental Considerations in Use

In applications like offshore oil platforms or marine equipment, Inconel 625’s resistance to corrosion reduces the risk of leaks or failures that could harm the environment. However, industries must ensure proper handling and disposal of any waste generated during machining or maintenance to prevent contamination.

Why Choose Precionn for Inconel 625 Machining?

At Precionn, we specialize in precision machining of advanced materials for high-performance industries. Our expertise includes working with complex alloys like Inconel 625, which we regularly machine for aerospace, marine, and energy sector clients.

Thanks to our state-of-the-art equipment and skilled workforce, we can handle the challenges of machining Inconel 625—from its hardness to its work-hardening behavior. Whether it’s turning, milling, or grinding, Precionn ensures top-quality results with tight tolerances.

If your project demands excellence in strength, corrosion resistance, and temperature performance, Inconel 625 may be the material of choice—and Precionn is your trusted partner to bring it to life.

Contact us today to learn more about how we can support your machining needs with Inconel 625 and other advanced materials.

FAQ: Common Questions About Inconel 625

It is generally non-magnetic in its annealed condition, making it suitable for applications where magnetic interference must be minimized. However, cold working or certain heat treatments can induce slight magnetism, though it remains minimal compared to ferromagnetic materials like steel.

Welding Inconel 625 requires careful preparation to maintain its properties. Gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) are commonly used, with filler metals like Inconel 625 or ERNiCrMo-3. Key considerations include:

Cleanliness: Ensure the workpiece is free of contaminants to prevent defects.

Heat Control: Use low heat input to avoid cracking or distortion.

Shielding Gas: Argon or helium-based gases protect the weld pool from oxidation.

Post-Weld Treatment: Stress-relief heat treatment may be needed for critical applications.

Skilled welders and proper equipment are essential for achieving high-quality welds with Inconel 625.

Inconel 625 does not rust in the traditional sense due to its high nickel and chromium content, which forms a protective oxide layer. This layer prevents oxidation and corrosion, even in harsh environments like seawater or acidic conditions. However, improper handling or exposure to extreme conditions could lead to localized corrosion if the protective layer is compromised.

Inconel 625 is generally harder than titanium, particularly in terms of its resistance to wear and deformation at high temperatures. While titanium is lighter and has a higher strength-to-weight ratio, Inconel 625’s superior hardness and corrosion resistance make it better suited for applications involving extreme environments.

Inconel 625 is significantly stronger than most stainless steels, especially at high temperatures. Its tensile strength and resistance to creep and fatigue surpass those of common stainless steel grades like 304 or 316. Additionally, Inconel 625’s corrosion resistance is superior in aggressive environments, making it a preferred choice for demanding applications.