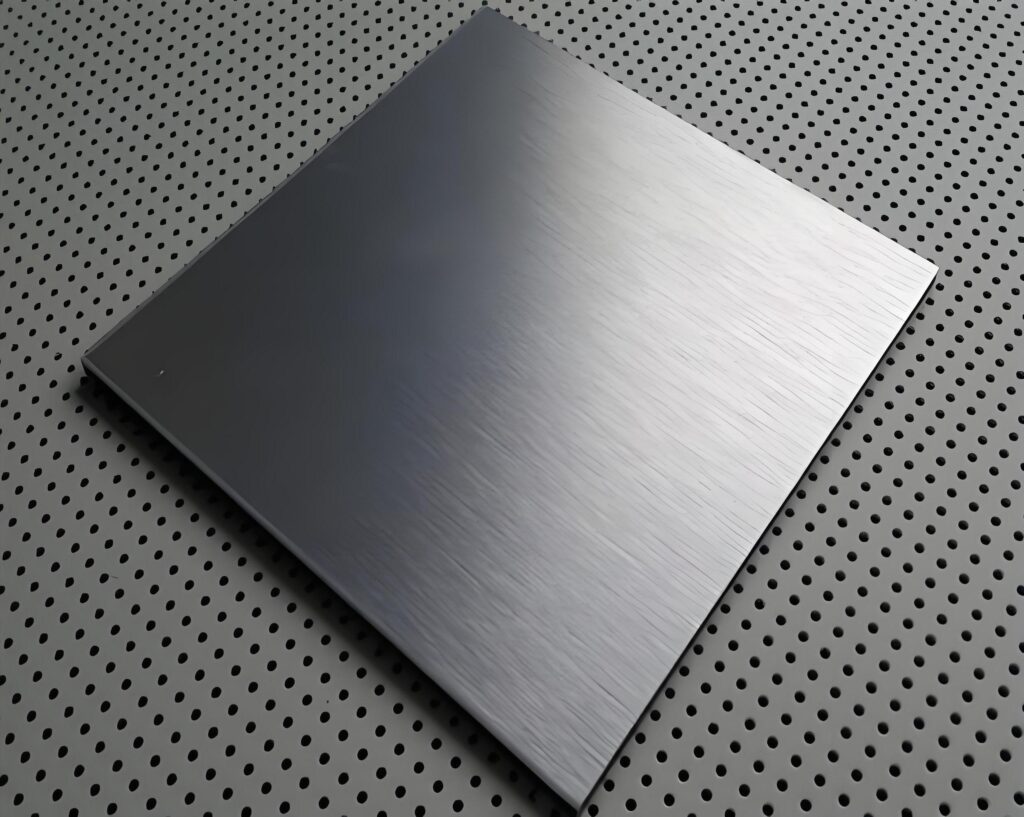

In the world of stainless steel, 304L is one of the most commonly used and trusted materials. It’s versatile, corrosion-resistant, and relatively easy to work with—qualities that make it a favorite in industries ranging from food processing to aerospace. But what exactly is 304L stainless steel, and why is it so popular?

This article takes a comprehensive look at 304L stainless steel: its chemical makeup, properties, benefits, limitations, and common applications. It also includes practical tips for machining and working with materials, helping manufacturers and engineers make the most of this stainless steel grade. Whether you’re new to metalworking or a seasoned professional, this guide provides clear, approachable information to help you better understand 304L stainless steel.

What is 304L Stainless Steel?

304L stainless steel is a low-carbon variant of the 304 grade, part of the 300 series of austenitic stainless steels. Austenitic steels are non-magnetic in their annealed state and can be strengthened through cold working, making them highly adaptable. The “L” in 304L signifies its low carbon content, capped at 0.035%, compared to 0.08% in standard 304 stainless steel. This reduction is critical for applications involving welding, as it minimizes the risk of sensitization—a process where chromium carbides form at grain boundaries, potentially leading to intergranular corrosion.

This grade is celebrated for its excellent corrosion resistance, particularly in environments with acids, alkalis, and moderate chloride exposure. Its ability to be easily formed and welded makes it a favorite in industries such as food and beverage, pharmaceuticals, architecture, and chemical processing. For example, 304L is used in kitchen equipment like sinks and saucepans, architectural facades like the Gateway Arch in St. Louis, and medical instruments that require frequent sterilization.

Applications of 304L Stainless Steel

- Food and Beverage Industry: 304L is ideal for tanks, pipes, and processing equipment because it resists corrosion from cleaning agents and does not affect food flavors.

- Architecture: Its aesthetic appeal and durability make it perfect for handrails, structural panels, and decorative elements.

- Medical and Pharmaceutical: Used in surgical tools and equipment due to its ability to withstand sterilizing solutions and high temperatures.

- Chemical Processing: Employed in tanks and piping where corrosive substances are handled, thanks to its weldability and corrosion resistance.

Typical chemical composition of 304L stainless steel:

- Chromium (Cr): 18.0–20.0%

- Nickel (Ni): 8.0–12.0%

- Carbon (C): ≤ 0.03%

- Manganese (Mn): ≤ 2.0%

- Silicon (Si): ≤ 1.0%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.03%

- Iron (Fe): Balance

These elements combine to offer a solid balance of corrosion resistance, strength, and workability.

304l stainless steel properties

Here are some of the notable mechanical properties of 304L stainless steel:

- Tensile Strength: ~485 MPa (70,000 psi)

- Yield Strength: ~170 MPa (25,000 psi)

- Elongation at Break: ~40%

- Hardness: ~70 HRB

- Density: 8.0 g/cm³

- Melting Point: ~1400–1450°C

The material remains non-magnetic in its annealed state but may become slightly magnetic when cold worked.

Key Characteristics

- Corrosion Resistance: 304L resists corrosion in atmospheric conditions, water, and many chemicals, making it ideal for food processing and chemical industries. Its low carbon content prevents intergranular corrosion post-welding.

- Formability: Its austenitic structure allows it to be shaped into complex forms through deep drawing, bending, or spinning, perfect for intricate components like kitchen sinks or medical devices.

- Weldability: Can be welded using TIG, MIG, or resistance welding without post-weld annealing, reducing production costs and time.

- Hygienic Properties: Its smooth, non-porous surface is easy to clean, making it suitable for applications requiring high hygiene standards.

- Thermal Stability: With a high melting point and low thermal conductivity, 304L performs well in high-temperature environments like heat exchangers.

These properties make 304L a reliable choice for applications requiring durability, hygiene, and ease of fabrication.

Limitations of 304L Stainless Steel

Despite its many advantages, 304L does have a few limitations:

- Not suitable for environments with high chloride concentrations

- Not as strong as martensitic or duplex stainless steels

- Can be prone to galling (seizing) during mechanical assembly

- May require passivation after welding for best corrosion resistance

Understanding these limitations can help engineers and fabricators choose the right material for their specific application.

Challenges and Solutions in Machining

Although 304L has good machinability, its work hardening property may lead to tool wear and surface finish issues. Work hardening refers to the phenomenon where the material becomes harder and more brittle during the machining process, which may increase the difficulty of cutting. To address this challenge, machining enterprises usually take the following measures:

- Using sharp tools: Keep the cutting edge sharp to reduce work hardening.

- Optimize cutting parameters: Adjust the cutting speed and feed rate to control heat accumulation.

- Using coolant: Effectively manage the heat generated during the processing, extend the lifespan of the cutting tools and improve the surface quality.

With these technologies, 304L stainless steel can be efficiently processed to produce components that meet strict tolerance requirements.

304L vs 304 Stainless Steel

While 304 and 304L stainless steels are similar, their differences in carbon content significantly impact their applications:

| Property | 304 Stainless Steel | 304L Stainless Steel |

| Carbon Content | ≤ 0.08% | ≤ 0.035% |

| Weldability | Moderate | Excellent |

| Corrosion Resistance | Good | Excellent (post-weld) |

| Cost | Slightly lower | Slightly higher |

Key Differences

- Carbon Content: The lower carbon in 304L reduces the risk of sensitization during welding, making it ideal for welded structures like tanks and pipes.

- Applications: 304 is suitable for non-welded applications like automotive trim or architectural panels, while 304L is preferred for welded components in corrosive environments.

- Strength: 304L may have slightly lower mechanical strength due to its reduced carbon, but this is negligible for most uses.

- Cost: 304 is marginally cheaper, but 304L’s enhanced weldability often justifies the slight cost increase.

Dual-certified 304/304L material is common, offering flexibility for applications where welding may or may not be required. For further reading, check Marlin Wire’s comparison.

304L vs 316L Stainless Steel

316L stainless steel is another low-carbon grade, but its composition includes molybdenum, which sets it apart from 304L:

| Property | 304L Stainless Steel | 316L Stainless Steel |

| Molybdenum Content | None | 2–3% |

| Corrosion Resistance | Good | Superior (chlorides) |

| Cost | Lower | Higher |

| Applications | General-purpose | Marine, chemical |

Key Differences

- Molybdenum: 316L’s 2–3% molybdenum enhances resistance to pitting and crevice corrosion, especially in chloride-rich environments like seawater.

- Corrosion Resistance: 316L outperforms 304L in harsh conditions, making it ideal for marine applications, chemical processing, and medical implants.

- Applications: 304L is used in food processing and inland architecture, while 316L is preferred for offshore oil rigs, boat fittings, and pharmaceutical equipment.

- Cost: 316L is more expensive due to molybdenum, but its superior performance in aggressive environments justifies the cost.

For a detailed comparison, see Thyssenkrupp Materials.

Choosing Between 304L and 316L

- Use 304L for cost-effective solutions in environments with low chloride exposure, such as kitchen equipment or inland structures.

- Use 316L for applications requiring superior corrosion resistance, such as coastal or marine settings or chemical processing with aggressive substances.

Conclusion

304L stainless steel is a versatile, reliable material that balances corrosion resistance, formability, and weldability. Its low carbon content makes it ideal for welded applications, preventing corrosion issues that could arise with higher-carbon grades like 304. Compared to 316L, it offers a cost-effective alternative for applications not requiring enhanced resistance to chlorides. Its wide use in industries like food processing, pharmaceuticals, and architecture underscores its adaptability and performance.

Precionn, a leader in the machining industry, harnesses the power of 304L stainless steel to deliver precision-engineered components. With a commitment to quality, Precionn ensures that every part meets the exacting standards of its clients, from food and beverage to medical and architectural sectors. For high-quality stainless steel solutions, Precionn is the trusted partner for precision and excellence.