Ferritic stainless steel is an important material used in many industries, known for its magnetic properties and good resistance to corrosion. Even for those new to metallurgy or materials science, understanding this material doesn’t have to be complicated. This guide explains the basics and provides insights into its composition, properties, applications, and how it compares to other types of stainless steel.

What is Ferritic Stainless Steel?

This category of stainless steel contains a high percentage of chromium and very little or no nickel. Its structure is primarily ferrite, a body-centered cubic (BCC) crystal structure. This ferritic structure is stable at all temperatures and is responsible for the steel’s magnetic properties.

This type is generally used where corrosion resistance is needed but the mechanical properties of austenitic stainless steel are not required. It’s often chosen because of its cost-effectiveness, due to the absence of nickel.

What Is Ferritic Stainless Steel Made Of?

The primary component is iron, just like all other types of steel. However, what distinguishes these grades is their specific alloying elements:

- Chromium (10.5% – 30%): The main element responsible for corrosion resistance.

- Low Carbon Content (< 0.1%): Reduces the risk of carbide precipitation and intergranular corrosion.

- Other Elements: Depending on the grade, elements like molybdenum, aluminum, titanium, and niobium may be added to enhance corrosion resistance, strength, and stability.

Notably, this type of stainless steel generally contains very low or no nickel, making it more economical and less susceptible to fluctuations in nickel prices.

Properties of Ferritic Stainless Steel

This steel offers a range of desirable properties:

- Magnetic: One of the simplest ways to identify it is by checking its magnetic properties.

- Good Corrosion Resistance: Especially in non-aggressive environments. Higher grades provide better corrosion protection.

- Oxidation Resistance: Performs well at elevated temperatures.

- Low Thermal Expansion: Less distortion during heating and cooling cycles.

- Good Formability: Easier to shape and bend compared to some other types.

- High Thermal Conductivity: Useful for applications that require quick heat dissipation.

However, this material generally has lower toughness and less ductility compared to austenitic grades.

Applications for Ferritic Stainless Steels

Due to their properties and cost advantages, these steels are widely used across multiple industries:

- Automotive: Exhaust systems, trim, and catalytic converter components.

- Architecture: Roofing, cladding, and decorative panels.

- Home Appliances: Washing machine drums, ovens, and kitchen sinks.

- Food Processing Equipment: Thanks to its corrosion resistance and ease of cleaning.

- Industrial Equipment: Heat exchangers and furnace components.

- Elevators and Escalators: Interior panels and structural parts.

How Is Ferritic Stainless Steel Processed?

Processing involves several key steps:

- Melting and Casting: Raw materials are melted in an electric arc furnace and then cast into slabs.

- Hot Rolling: The slabs are rolled at high temperatures to produce sheets or plates.

- Annealing: Heating the steel to relieve internal stresses and improve ductility.

- Pickling: A chemical treatment to remove surface oxides formed during annealing.

- Cold Rolling (if needed): For thinner gauges and improved surface finish.

- Final Annealing and Pickling: To restore mechanical properties and a clean surface.

Unlike austenitic types, these cannot be hardened through heat treatment, which simplifies some aspects of processing but limits applications where high hardness is required.

What Are the Different Types of Ferritic Stainless Steel Grades?

Ferritic stainless steel comes in a variety of grades, each tailored for specific applications. These grades are classified into five groups based on their composition and properties:

Group 1: Basic Grades (e.g., 409)

These are the most affordable ferritic stainless steels, with lower chromium content (around 10.5–11.7%). They’re often used in automotive exhaust systems where moderate corrosion resistance is needed.

Group 2: Enhanced Corrosion Resistance (e.g., 430)

With slightly higher chromium content (16–18%), these grades offer better corrosion resistance and are commonly used in household appliances like dishwashers and refrigerators.

Group 3: Improved Strength and Corrosion Resistance (e.g., 434, 436)

These grades include molybdenum for added strength and resistance to pitting corrosion. They’re ideal for more demanding applications like automotive trim or industrial equipment.

Group 4: High-Temperature Grades (e.g., 442)

Designed to withstand higher temperatures, these grades are used in applications like furnace parts or heat exchangers.

Group 5: Specialized Grades (e.g., 444)

These high-performance grades have higher chromium and molybdenum content, making them suitable for harsh environments like marine applications or chemical processing.

Each group offers a unique combination of properties, allowing manufacturers to choose the perfect grade for their needs.

What Is the Difference Between Ferritic Stainless Steel and Martensitic Stainless Steel?

While both are magnetic and contain chromium, they differ in several key aspects:

- Structure: One has a BCC structure; the other can be hardened into a body-centered tetragonal (BCT) structure.

- Hardening: Martensitic can be hardened by heat treatment; the other cannot.

- Toughness: Ferritic generally has better toughness and formability.

- Applications: Martensitic is used in cutlery and tools; the other is more for structural and decorative purposes.

What Is the Difference Between Ferritic Stainless Steel and Austenitic Stainless Steel?

These are the two most common types of stainless steel and have very different properties:

- Structure: Austenitic has a face-centered cubic (FCC) structure; ferritic has a BCC structure.

- Magnetism: Austenitic is non-magnetic; ferritic is magnetic.

- Nickel Content: Austenitic contains high nickel levels; ferritic contains little or none.

- Formability and Weldability: Austenitic has better formability and weldability in most cases.

- Corrosion Resistance: Austenitic typically offers superior corrosion resistance.

What Are the Benefits of Ferritic Stainless Steel?

- Cost-Effective: Low or no nickel content reduces cost.

- Good Corrosion Resistance: Particularly in mildly corrosive environments.

- Magnetic Properties: Useful in applications where magnetism is required.

- High Thermal Conductivity: Better than austenitic steels.

- Low Thermal Expansion: Reduces risk of warping or deformation.

- Good Resistance to Stress Corrosion Cracking: Especially in chloride-rich environments.

What Are the Limitations of Ferritic Stainless Steel?

- Lower Ductility and Toughness: Especially at low temperatures.

- Limited Hardenability: Cannot be hardened by heat treatment.

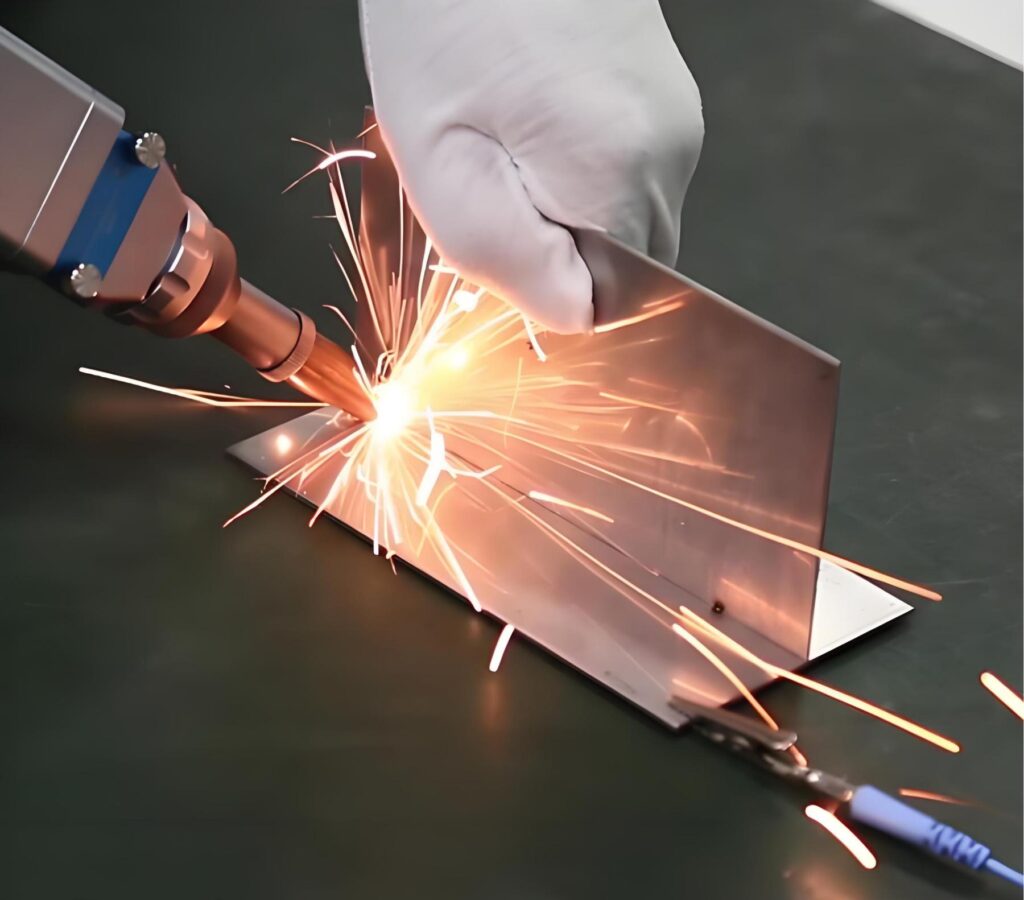

- Weldability Issues: Some grades are prone to grain growth during welding.

- Reduced Corrosion Resistance Compared to Austenitic Grades: Not suitable for highly aggressive environments.

About Precionn

Precionn is a trusted name in the machining industry, providing precision solutions tailored to a wide range of materials and specifications. With a strong focus on quality, innovation, and customer satisfaction, Precionn has built a reputation for excellence in manufacturing components from a variety of materials, including stainless steels like ferritic grades. Our state-of-the-art facility and skilled team ensure that each project is completed with the utmost accuracy and reliability. Whether you’re in the automotive, industrial, or architectural sector, Precionn is your reliable partner for precision machining.

FAQ:

Are Ferritic Stainless Steels Durable?

Yes, these steels are quite durable in the right environments. They offer good resistance to corrosion and oxidation, making them suitable for automotive, architectural, and industrial uses.

Does ferritic stainless steel rust?

While generally tougher than martensitic types, these materials can be somewhat brittle at very low temperatures. However, newer grades have improved toughness.

Will Ferritic Stainless Steel Rust?

All stainless steels can rust under extreme conditions. However, these grades offer good resistance to rust in normal atmospheric conditions, especially those with higher chromium and added stabilizers.

Can Ferritic Stainless Steel Be Welded?

Yes, many of these grades can be welded, although some require special considerations due to grain growth or brittleness. Stabilized grades like 439 and 441 offer better weldability.

Can You Harden Ferritic Stainless Steel?

No, these steels cannot be hardened through heat treatment. However, some grades can be strengthened by cold working.