Steel is one of the most versatile and widely used materials in modern industry, found in everything from construction to medical devices. At Precionn, a leading precision machining company, understanding the properties of materials is at the core of delivering high-performance solutions. One question we often encounter is: Is steel magnetic? The answer may not be as straightforward as it seems. This blog delves into the magnetic properties of steel, exploring what makes it magnetic or non-magnetic, how various factors influence its magnetism, and where magnetic steel is commonly applied.

What is Steel?

Steel is an alloy primarily composed of iron and carbon, with trace amounts of other elements like manganese, chromium, or nickel. Its versatility stems from the ability to adjust its composition to achieve desired properties, such as strength, durability, or corrosion resistance. In machining, steel is a cornerstone material due to its robustness and adaptability, making it ideal for components in industries ranging from automotive to aerospace.

The composition of steel varies depending on its intended use. For instance, carbon steel contains a higher percentage of carbon for increased hardness, while stainless steel includes chromium for corrosion resistance. At Precionn, we work with various steel types to create precision parts, and understanding their properties, including magnetism, is critical to delivering top-tier results.

Is Steel Magnetic?

The short answer is: it depends. Not all steel is magnetic. The magnetic properties of steel are primarily determined by the type of steel and its internal crystalline structure.

Steel is mostly made from iron, which is a ferromagnetic material. This means pure iron is strongly attracted to magnets. However, when other elements are added to create steel alloys, the resulting magnetic properties can change dramatically.

For instance:

- Carbon steel is typically magnetic.

- Stainless steel, particularly the austenitic types (like 304 or 316), are generally not magnetic.

- Ferritic and martensitic stainless steels often retain some magnetic qualities.

Therefore, while many types of steel are magnetic, others are not. Understanding the reasons why is crucial for selecting the right material for specific industrial purposes.

The Reasons That Affect Steel Magnetics

Several factors influence whether steel exhibits magnetic properties and to what extent. Understanding these factors is essential for industries relying on steel’s performance.

Alloy Composition

The presence of alloying elements like nickel, chromium, or molybdenum can significantly affect steel’s magnetism. For instance, adding nickel to steel, as in austenitic stainless steel, stabilizes the non-magnetic austenitic phase, reducing magnetism. Conversely, ferritic stainless steels, with lower nickel content, remain magnetic.

Crystal Structure

As mentioned earlier, the crystal structure of steel determines its magnetic behavior. Ferritic and martensitic steels have structures conducive to magnetism, while austenitic steels do not. This structural difference explains why 430 stainless steel (ferritic) is magnetic, while 304 stainless steel (austenitic) is not.

Heat Treatment and Processing

Manufacturing processes like heat treatment, annealing, or cold working can alter steel’s magnetic properties. For example, annealing can relieve stresses in the material, potentially reducing magnetism in some cases, while cold working can induce magnetism in austenitic steels by transforming their structure.

External Magnetic Fields

Exposure to external magnetic fields can temporarily or permanently magnetize steel. This is particularly relevant in applications where steel components are used in motors or magnetic assemblies, as prolonged exposure can enhance or alter their magnetic properties.

Temperature Effects

Temperature can also impact magnetism. At high temperatures, ferromagnetic materials may lose their magnetism as thermal energy disrupts the alignment of magnetic domains. This phenomenon, known as the Curie point, varies depending on the steel’s composition.

At Precionn, we account for these factors when machining steel components, ensuring that the final product meets the magnetic and functional requirements of our clients’ applications.

Magnetic Steel Applications

The magnetic properties of steel are crucial in many industries. Here’s how magnetic and non-magnetic steels are used in practical applications:

Magnetic Steel

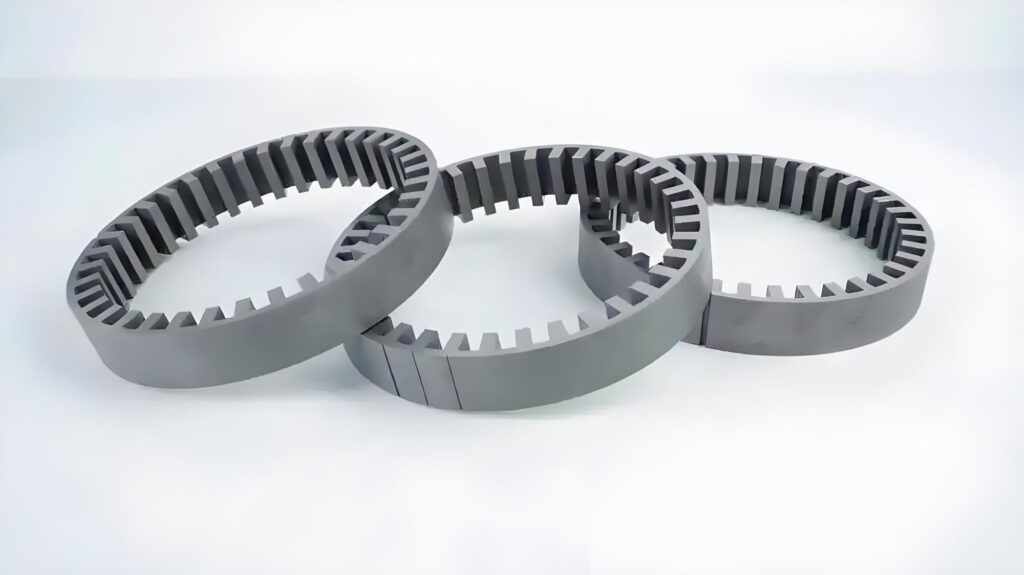

- Electric Motors and Transformers Magnetic steels are essential in the cores of transformers and electric motors due to their ability to channel magnetic fields efficiently.

- Magnetic Storage Devices Hard drives and tapes use magnetic steel components for data storage.

- Security Systems Magnetic steels are used in sensors and detection systems for controlling access or triggering alarms.

- Machinery and Industrial Equipment Magnetic properties are advantageous in machines requiring magnetic coupling, braking, or holding features.

Non-Magnetic Steel

- Medical Equipment MRI machines require non-magnetic tools and components to avoid interference with the magnetic field.

- Aerospace Non-magnetic stainless steels are used where magnetic interference can disrupt navigation systems.

- Food Processing Non-magnetic stainless steels offer excellent hygiene and corrosion resistance, ideal for food-grade machinery.

The Role of Magnetism in Material Selection

When choosing materials for machining, magnetism is often a critical consideration. For applications requiring strong magnetic properties, ferritic or martensitic steels are preferred. In contrast, non-magnetic austenitic steels are chosen for environments where magnetism could interfere with performance, such as in sensitive electronic equipment.

Testing for magnetism is a common practice in quality control. Simple tests, like using a magnet to check attraction, can confirm a material’s magnetic properties. At Precionn, we integrate such tests into our processes to ensure that every component meets the specified requirements, whether magnetic or non-magnetic.

Environmental and Practical Considerations

The magnetic properties of steel also have implications for recycling and sustainability. Magnetic steel is easier to sort and recycle using magnetic separation techniques, contributing to efficient material recovery. This aligns with modern industry goals of reducing waste and promoting sustainability, values that Precionn supports through responsible manufacturing practices.

Practically, understanding steel’s magnetism helps prevent issues in applications where unintended magnetic fields could cause problems. For example, in electronics, non-magnetic steel may be chosen to avoid interference with sensitive components.

Advances in Magnetic Steel Research

Ongoing research continues to enhance the magnetic properties of steel. Innovations in alloy design and processing techniques are leading to new types of magnetic steel with improved performance. For instance, high-strength magnetic steels are being developed for advanced applications in renewable energy and electric vehicles.

At Precionn, we stay abreast of these developments to ensure our machining processes incorporate the latest advancements in material science. This allows us to deliver cutting-edge solutions to our clients across various industries.

Conclusion

The question “Is steel magnetic?” opens the door to a deeper understanding of this versatile material. While the answer depends on the type of steel, its composition, and processing, the magnetic properties of steel play a crucial role in its applications across industries. From electrical systems to medical devices, magnetic steel is a cornerstone of modern manufacturing.

At Precionn, we pride ourselves on our expertise in precision machining and our ability to work with a wide range of steel types, whether magnetic or non-magnetic. By understanding the science behind steel’s magnetism, we deliver tailored solutions that meet the unique needs of our clients. For more insights into materials and machining, visit our website at Precionn’s official site and explore how we can bring precision to your projects.