Galvanized steel has become an integral part of modern manufacturing, known for its durability, corrosion resistance, and wide range of applications. At Precionn, a trusted name in the machining industry, understanding materials at a fundamental level is part of delivering precision-engineered results. This article explores the essentials of galvanized steel—from its properties to its practical applications.

What is Galvanized Steel?

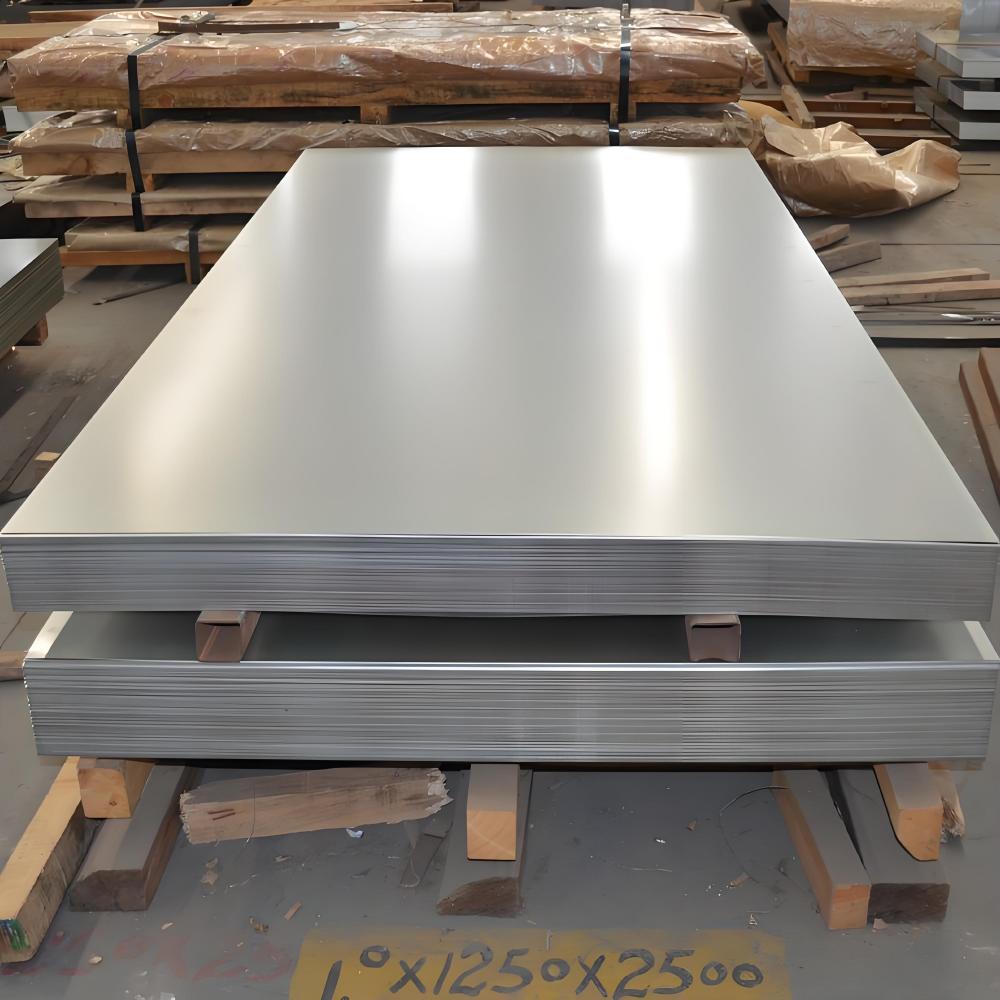

Galvanized steel is steel coated with a layer of zinc to protect it from corrosion. This process, known as galvanization, enhances the material’s durability, making it suitable for environments exposed to moisture, salt, or other corrosive elements. The zinc coating acts as a sacrificial anode, corroding before the steel, thereby extending the material’s lifespan.

This versatile material is widely used across industries, from construction beams to automotive parts. Its ability to resist rust while maintaining structural integrity makes it a go-to choice for projects requiring longevity and reliability.

Properties of Galvanized Steel

Galvanized steel boasts several properties that make it stand out. These include:

- Corrosion Resistance: The zinc coating provides a protective barrier, significantly reducing rust formation even in harsh environments.

- Durability: Galvanized steel is robust and can withstand physical stress, making it ideal for heavy-duty applications.

- Cost-Effectiveness: Compared to other corrosion-resistant materials like stainless steel, galvanized steel is more affordable without compromising quality.

- Low Maintenance: The protective zinc layer reduces the need for frequent maintenance, saving time and costs over the material’s lifespan.

- Versatility: Available in various forms, such as sheets, pipes, and coils, galvanized acier adapts to diverse project needs.

These properties make galvanized steel a preferred material for industries seeking reliable, long-lasting solutions.

How Does the Galvanizing Steel Process Work?

The galvanizing process involves coating steel with zinc to enhance its resistance to corrosion. The most common method is hot-dip galvanizing, which includes the following steps:

- Surface Preparation: The steel is cleaned to remove dirt, oil, and rust, typically through degreasing, pickling, and fluxing.

- Submersion in Zinc: The cleaned steel is submerged in a bath of molten zinc, typically at temperatures around 450°C (840°F). This allows the zinc to bond with the steel surface.

- Cooling and Inspection: After removal from the zinc bath, the steel cools, and the zinc coating solidifies. The material is then inspected for coating uniformity and quality.

This process ensures a strong, uniform zinc layer that protects the steel from environmental damage.

Methods of Galvanizing Steel

There are several methods to galvanize steel, each suited to specific applications:

Hot-Dip Galvanizing

This is the most common method, where steel parts are dipped into molten zinc. It provides a thick, durable coating ideal for large structures like bridges and guardrails.

Electro-Galvanizing

In this method, an electric current deposits a thin zinc layer onto the steel. It’s often used for smaller components requiring a smooth, aesthetic finish, such as automotive parts.

Sherardizing

This involves heating steel parts in a zinc powder-filled container. The zinc diffuses into the steel surface, creating a uniform coating suitable for small, intricate parts.

Zinc Spraying (Metallizing)

Zinc is sprayed onto the steel surface using a specialized gun. This method is used for large structures that cannot be submerged in a zinc bath.

Each method offers unique benefits, allowing manufacturers to choose the best approach based on project requirements.

Galvanized Steel Use for?

Galvanized steel’s versatility makes it a staple in numerous industries. Some common applications include:

- Construction: Used in structural beams, roofing, and siding due to its durability and weather resistance.

- Automotive: Employed in car bodies, chassis, and exhaust systems for its corrosion resistance and strength.

- Agriculture: Ideal for fencing, silos, and irrigation systems exposed to outdoor conditions.

- Infrastructure: Found in guardrails, streetlights, and utility poles for its long lifespan and low maintenance.

- Manufacturing: Utilized in HVAC systems, ductwork, and industrial equipment where durability is key.

The adaptability of galvanized steel ensures it meets the demands of both heavy-duty and aesthetic applications.

Advantages and Disadvantages of Galvanized Steel

Like any material, galvanized steel has its strengths and limitations.

Advantages

- Longevity: The zinc coating can extend the steel’s lifespan by decades, even in harsh environments.

- Cost-Effective: Offers corrosion resistance at a lower cost than alternatives like stainless steel.

- Low Maintenance: Requires minimal upkeep, reducing long-term costs.

- Versatility: Suitable for a wide range of applications, from structural to decorative.

Disadvantages

- Limited Coating Life: In highly corrosive environments, the zinc coating may eventually wear off, requiring recoating.

- Not Suitable for High Temperatures: Prolonged exposure to temperatures above 200°C (390°F) can damage the zinc coating.

- Aesthetic Limitations: The galvanized finish may not be as visually appealing as other materials for certain applications.

Understanding these pros and cons helps in selecting galvanized steel for the right projects.

Galvanized Steel in Modern Industry

The role of galvanized steel in modern industry cannot be overstated. Its ability to resist corrosion while remaining cost-effective makes it a go-to material for projects requiring durability and reliability. From skyscrapers to farm equipment, galvanized steel supports critical infrastructure worldwide. Advances in galvanizing techniques continue to improve its performance, ensuring it remains relevant in an ever-evolving industrial landscape.

Choosing the Right Material for Your Project

Selecting the right material is crucial for project success. Galvanized steel offers a balance of strength, corrosion resistance, and affordability, making it suitable for a wide range of applications. However, factors like environmental conditions, temperature exposure, and aesthetic requirements should guide material selection. Consulting with experts can help determine if galvanized steel is the best fit for your needs.

Sustainability and Galvanized Steel

Galvanized steel is an environmentally friendly choice. The zinc coating is recyclable, and the steel itself can be reused, reducing waste. Additionally, its long lifespan minimizes the need for frequent replacements, conserving resources. For companies prioritizing sustainability, galvanized steel aligns with eco-conscious goals without sacrificing performance.

Working with Precionn for Your Galvanized Steel Needs

At Precionn, we understand the importance of high-quality materials in achieving project success. Our expertise in precision machining allows us to work with galvanized steel to deliver components that meet the highest standards. Whether you need custom parts for construction, automotive, or industrial applications, our team is here to provide tailored solutions. Contact Precionn today to learn how we can support your next project with galvanized steel expertise.

FAQ:

Galvanized steel gained popularity due to its excellent corrosion resistance, affordability, and versatility. Since its development in the 19th century, it has been a cost-effective solution for industries needing durable materials. Its ability to withstand harsh weather and reduce maintenance costs has made it a favorite in construction, agriculture, and infrastructure.

Galvanized steel is generally safe for most applications. The zinc coating is non-toxic and widely used in food storage and water systems. However, inhaling zinc oxide fumes from welding or cutting galvanized steel can cause temporary health issues, known as “metal fume fever.” Proper ventilation and safety measures mitigate this risk.

Yes, galvanized steel can be painted, but the surface requires preparation. The zinc coating must be cleaned and primed with a zinc-compatible primer to ensure paint adhesion. This allows for customization while maintaining corrosion resistance.

Drilling holes in galvanized steel is possible with standard tools, such as high-speed steel or cobalt drill bits. However, care must be taken to avoid damaging the zinc coating. Using a lubricant and drilling at a low speed can minimize coating disruption.

Galvanized square steel is a type of steel tubing with a square cross-section that has been coated with a layer of zinc through a process called galvanization. This zinc coating protects the steel from corrosion, making it durable and resistant to rust, ideal for outdoor or harsh environments. It’s commonly used in construction, fencing, furniture, and structural applications due to its strength, versatility, and cost-effectiveness. The square shape provides uniform strength and stability in multiple directions.