304 Stainless Steel is widely recognized for its impressive balance of strength, durability, and resistance to corrosion. Whether found in everyday kitchen tools or precision-engineered industrial components, this alloy stands out as a trusted choice across sectors. Its ability to perform in both standard and demanding environments has made it a mainstay material for decades. This article provides a detailed overview of how 304 stainless steel is used, how it compares to other grades, and what to consider when selecting it for various applications.

What is 304 Stainless Steel?

304 stainless steel is one of the most widely used stainless steel alloys in the world. Known for its excellent corrosion resistance, good formability, and a wide range of industrial and domestic applications, 304 stainless steel has become a preferred material in various industries. It belongs to the austenitic family of stainless steels and contains a high level of chromium and nickel.

Composition of 304 Stainless Steel

304 stainless steel typically contains:

- Chromium: 18-20%

- Nickel: 8-10.5%

- Carbon: Maximum 0.08%

- Manganese: Maximum 2%

- Silicon: Maximum 1%

- Phosphorus: Maximum 0.045%

- Sulfur: Maximum 0.03%

- Iron: Balance

This specific combination of elements gives 304 stainless steel its strength, corrosion resistance, and ability to withstand high temperatures.

Properties of 304 Stainless Steel

Chemical Composition: The Foundation of Performance

The chemical makeup of 304 stainless steel largely defines its outstanding qualities. With roughly 18% chromium and 8% nickel, this alloy is specially designed to resist oxidation and corrosion in many environments. It also contains small amounts of carbon, manganese, and silicon, which help improve its mechanical strength and durability without compromising corrosion resistance.

Mechanical Properties: Strength Meets Flexibility

When it comes to strength, 304 stainless steel doesn’t disappoint. It boasts a tensile strength typically between 515 and 750 MPa and a yield strength of about 205 MPa, making it strong enough for a wide range of structural and mechanical applications. What’s more, it offers excellent elongation—about 40%—meaning it can flex and bend without breaking, a crucial feature for forming processes and manufacturing complex shapes.

Physical Properties: Durable and Lightweight

Density of stainless steel 304 is 7.93 g/cm³, which gives it a sturdy yet manageable weight for industrial use. 304 stainless steel melting point ranges between 1400 and 1450 °C, allowing it to withstand high temperatures in many applications. Additionally, it has moderate thermal conductivity and is mostly non-magnetic in its annealed state, which can be important in certain electrical and mechanical contexts.

Corrosion Resistance: Built to Last

One of the standout features of 304 stainless steel is its excellent corrosion resistance. It resists rust and staining in most atmospheric environments and is especially effective against many food acids and chemicals. However, it is less suited for environments with high chloride concentrations, such as seawater, where other grades like 316 stainless steel might be preferred.

Fabrication and Workability: Easy to Shape and Weld

304 stainless steel is known for its great workability. It can be easily formed into sheets, pipes, and intricate components through rolling, bending, and stamping. It also welds well with standard techniques, making it a favorite material for manufacturing. While it can be machined, care must be taken because it tends to harden quickly during cutting.

Heat Resistance: Reliable Under Pressure

This stainless steel grade maintains its integrity under elevated temperatures up to around 870 °C for continuous use, and even higher for short periods. It’s suitable for applications involving heat exposure but should be avoided in environments where it would remain at temperatures between 425 and 860 °C for extended times, as this can affect its corrosion resistance.

Hygienic and Aesthetic Qualities

Thanks to its smooth, non-porous surface, 304 stainless steel is easy to clean and sterilize, which is why it’s extensively used in food processing, kitchens, and medical environments. Its natural shine and ability to maintain polish also make it a popular choice in architectural and consumer product design.

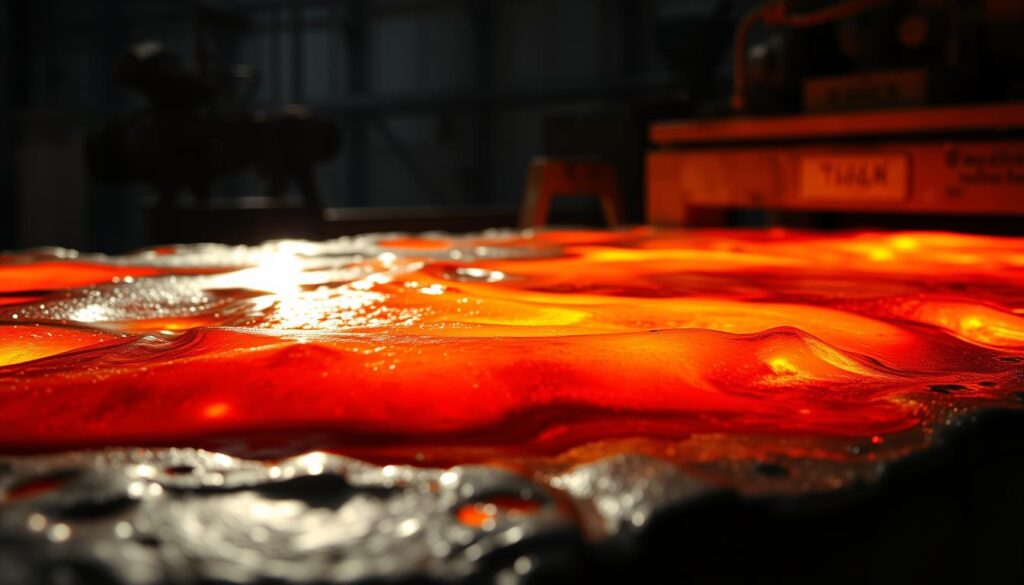

Melting Point of 304 Stainless Steel

The melting point of 304 stainless steel ranges between 1400°C to 1450°C (2552°F to 2642°F). This high melting temperature allows 304 to maintain its structural integrity under elevated heat conditions, making it suitable for use in applications involving sustained exposure to heat, such as heat exchangers, furnace parts, and certain welded structures.

However, it is important to note that while 304 does not melt below this range, it may begin to lose strength and become less ductile at much lower temperatures (above 870°C or 1600°F), which can affect performance in high-temperature service.

Yield Strength of 304 Stainless Steel

The yield strength of 304 stainless steel is typically around 215 MPa (31,000 psi). Yield strength represents the amount of stress the material can endure before it begins to deform permanently. This makes 304 suitable for moderate-load applications where both strength and corrosion resistance are required.

For cold-worked 304 stainless steel (such as in drawn or formed shapes), the yield strength can increase significantly—reaching over 500 MPa, depending on the degree of work hardening.

When compared to other materials:

- Mild Steel: ~250 MPa

- 316 Stainless Steel: ~290 MPa

- Aluminum 6061-T6: ~276 MPa

Although not as strong as some heat-treated or specialty alloys, 304’s combination of moderate strength and excellent ductility allows it to perform well in structural, mechanical, and pressure-handling applications—particularly where corrosion protection is crucial.

304 stainless steel hardness

Typically around 70 HRB (Rockwell B scale). This corresponds to approximately 150–200 Brinell Hardness (HB), depending on processing conditions. While not as hard as martensitic grades, 304’s hardness is sufficient for many structural and consumer applications. It also offers excellent toughness and is not prone to brittleness even at low temperatures.

Applications of 304 Stainless Steel

304 stainless steel is one of the most widely used austenitic stainless steel grades across various industries. Composed primarily of chromium (18%) and nickel (8%), it offers excellent corrosion resistance, durability, and ease of fabrication. Thanks to its balanced properties and affordability, it is a go-to material for applications ranging from architecture to food processing and medical equipment. Let’s explore the most common uses of 304 stainless steel across different sectors.

Construction and Architecture

In the construction industry, 304 stainless steel is highly valued for its strength and aesthetic appeal. It is used in structural components, roofing, wall cladding, and stainless steel handrails. Architects often choose it for modern buildings due to its clean finish and ability to resist weathering and oxidation. The material’s durability and corrosion resistance make it ideal for both interior and exterior applications, especially in coastal or urban environments.

Food and Beverage Industry

One of the largest consumers of 304 stainless steel is the food and beverage industry. As a food-grade stainless steel, it is non-reactive, easy to clean, and resistant to acidic substances. It is used in the manufacturing of kitchen equipment, stainless steel sinks, food processing tanks, and commercial cookware. Additionally, 304 stainless steel cookware is popular in households for its heat retention, durability, and hygienic properties.

Industrial Equipment and Chemical Processing

In industrial environments, 304 stainless steel is widely used for its excellent resistance to chemicals and high temperatures. It’s a key material in chemical tanks, heat exchangers, piping systems, and wastewater treatment equipment. Because it maintains strength and integrity in harsh environments, it is a trusted choice for manufacturers in the chemical, pharmaceutical, and oil & gas sectors.

Automotive and Transportation

The automotive industry uses 304 stainless steel in exhaust systems, trims, and structural components. It is also used in train and subway car interiors, where resistance to vibration and wear is crucial. Its light weight, corrosion resistance, and ability to withstand high temperatures make it suitable for modern, fuel-efficient vehicles.

Mechanical Parts and Fasteners

304 stainless steel is a top choice in the machinery and manufacturing sectors. It is commonly used for bolts, nuts, springs, and other precision parts that require strength and corrosion resistance. Its good weldability and formability allow for easy machining, making it a preferred material in automated assembly lines and custom fabrication.

Medical and Pharmaceutical Applications

In the medical field, 304 stainless steel is used in the production of surgical tools, hospital furniture, trays, and sterilizable storage units. It is also applied to pharmaceutical processing equipment, where hygiene and resistance to sterilization chemicals are critical. Although 316 stainless steel is more corrosion-resistant, 304 remains cost-effective for non-critical medical tools and components.

Appliances and Consumer Goods

From kitchen appliances to consumer electronics, 304 stainless steel is everywhere. It’s used in washing machines, refrigerator doors, microwave ovens, and electric kettles. Consumers value it for its polished appearance, low maintenance, and long life span. The material also provides a modern, clean look that enhances product design.

Is 304 Stainless Steel Food Grade?

Yes, 304 stainless steel is considered food grade. It is commonly used in kitchen appliances, cookware, food processing equipment, and utensils. Its non-reactive nature makes it ideal for handling acidic and alkaline foods.

Does 304 Stainless Steel Rust?

304 stainless steel is often described as “rust-proof,” but technically, it is highly rust-resistant, not completely immune. The alloy’s high chromium content (18-20%) allows it to form a thin, invisible layer of chromium oxide on its surface. This passive layer shields the material from environmental elements, preventing oxidation and rust formation under normal conditions.

However, in environments with high salinity (such as coastal areas), high humidity, or exposure to strong chlorides (e.g., pool chemicals, de-icing salts, or bleach), this protective layer can break down. When that happens, pitting or crevice corrosion may occur—leading to visible rust spots or surface deterioration over time.

Common examples where 304 stainless steel may rust include:

- Outdoor installations near the ocean

- Industrial environments with harsh chemicals

- Poor maintenance or contact with iron contaminants

Despite this, for indoor use and general-purpose applications—especially in kitchens, food processing, medical facilities, and architectural finishes—304 stainless steel remains one of the most rust-resistant and reliable materials available.

About US

Precionn is a trusted name in the machining industry, specializing in high-precision components made from materials like stainless steel 304. With advanced technology, strict quality control, and a commitment to customer satisfaction, Precionn delivers excellence in every part produced. Our team understands the unique properties and challenges of working with 304 stainless steel, ensuring that every product meets the highest standards. Visit our website to learn more about our capabilities and how we can support your next project.